Showing posts with label CDI. Show all posts

Showing posts with label CDI. Show all posts

Tuesday, October 20, 2015

CRM250 MD24 CDI no spark problem

CRM250 MD24 is a 2-stroke enduro motorcycle commonly found in UK is very rare to be found in ASIA-Pacific. There are too many model of this actually and the one being the MD24 93" will be discussed. Apparently this post is the conclusion of a dear friend to whom who wrote the problem to me via electronic mail " how good the internet can bring up two people opposite of the globe to communicate and resolve some problem as if we are neighbors"...

The problem was the CDI which is costly refuses to give a spark. All external component that directs to the ignition controller are all good and thus only the cdi was the suspect.The motorcycle was on a restoration process, and only the ignition was the problem. I had asked his permission to post all the photos here for others who has the same problem that may help you just in case.

Of course, in order for you to do so is stripped all of the epoxy resin that covers the whole black box to expose the board which is very tricky and extra care and more patience is needed. All components must be intact to the board or else it will be much harder to determine what component had failed. Servicing a defective Ignition Controller is difficult and have to isolate each and one block from one another.

Through e-mail, he sent me all the photos needed as shown.

Figure 1 shows the capacitor with 1.5uf /400 volts

Figure 2 shows The MCU and Pulse shaping IC

Figure 3 is PIN-OUT label of the CDI

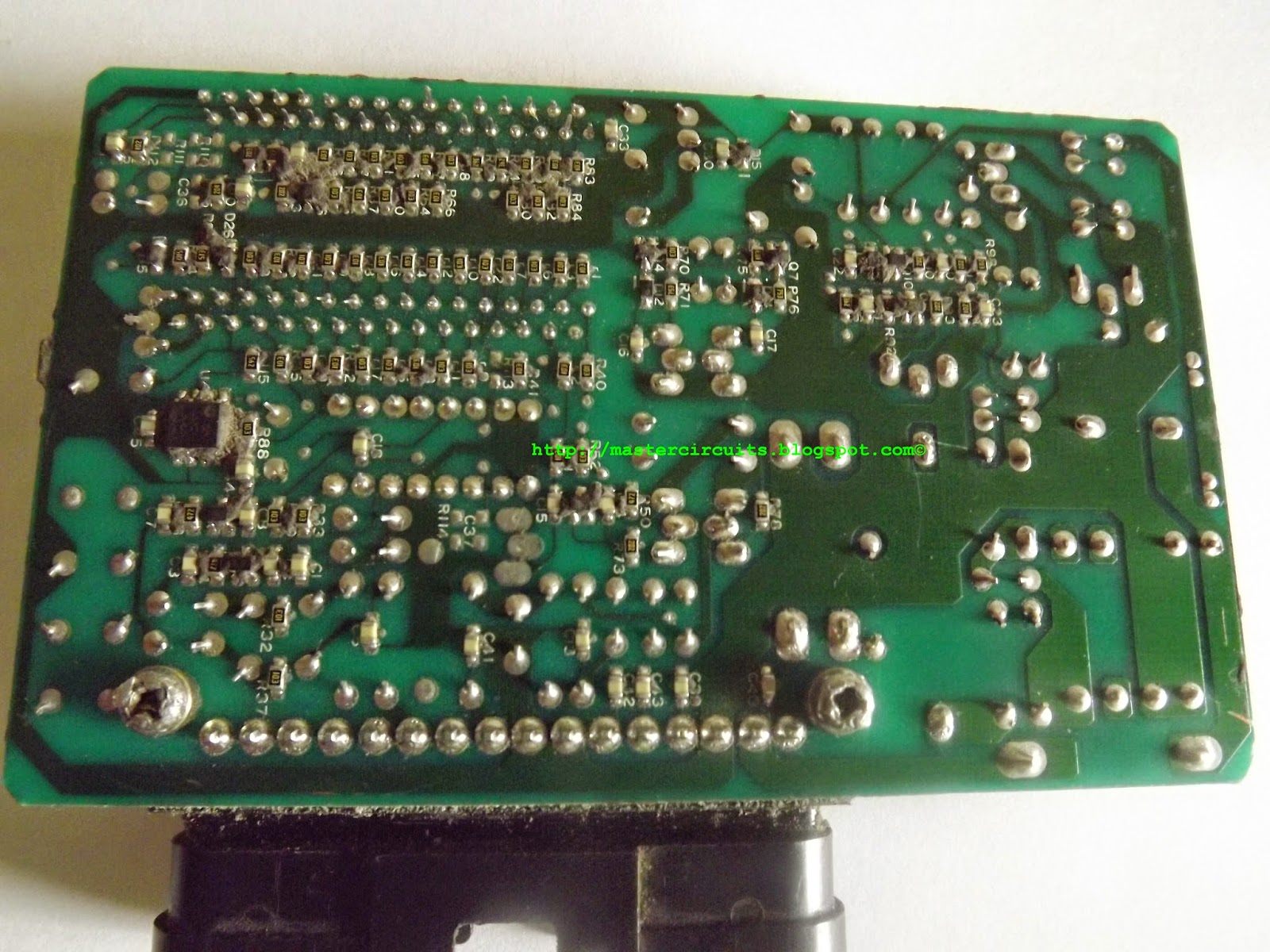

Figure 4 shows Smd components at the solder side of the cdi

Figure 5 Component Side View of this cdi

Figure 6 Here, he label the troubleshooting process with voltages reading.

Figure 7 is the Wiring color code of the cdi

By the way, the CDI of CRM250 MD24 is an AC-CDI type, it has an external high voltage exciter coil that charges the capacitor as the engine is turn. This means that the higher the engine rpm, the higher the voltage can be measured at the charging capacitor.

Moving on finding the culprit of the no spark symptoms of this cdi. Test was done trying to find why it refuses to spark at the tip of the spark plug. Figure 6 shows the voltage reading from turning the engine indicates that there is a voltage at the anode pin of the thyristor. This means that the high voltage of the generator is getting inside, indicating a healthy High voltage generator. One pin of the charging capacitor is connected to that cathode pin of the switching thyristor (SCR), hence there will be voltage, but there will be no vltage at the other pin if your reference is ground, since the charge can only be dumped to the ignition coils primary winding, which act as the load when the SCR is triggered by the MCU. If all is good, the charge will then be dumped causing a momentary magnetic field to that winding and transferred it to the secondary winding in a x10 ratio which is enough to create spark at the tip of the spark plug.

And that is where the problem exist. It does not create any spark. Hence, with the existence of voltage across the capacitor.(by the way to see the voltage is being kept by the capacitor before the dump, put the voltage meter probe across the two pins on the charging capacitor. Voltage will remain there up until the SCR is triggered.)

So before the capacitor, the circuit is generally good. but then the output towards the ignition coil output is not. Generally, If you look at all CDI schematic posted all over the internet, there is still a major component after the pin of the charging capacitor..(did u notice it)

Here is an example, looking at Fig. 8, the RED BOX outline comprises the SCR, the charging capacitor, and a DAMPING DIODE, all cdi must have that diode to protect the SCR and other circuits from getting the HV back after the dump. It is actually connected in parallel to the ignition coil.

That DIODE in regards to the CRM250 MD24 photo,was traced and looking at Fig. 5. designated as D16..

And guess what, It is actually shorted. If that is already shorted then the path of the charging capacitor is nearly directs to ground and no charge will be directed to the ignition coil..

In other words, when the damping diode is already shorted, the charge will no longer flow to the ignition coil, and the system is stopped. Seems odd..that is how it works.

Many will think how the damping diode actually get blown. SIMPLE

if the ignition coil is removed from the circuit and tried to turn the engine without it. The diode will then get the ACTUAL charged of the capacitor and dumps it to ground. It is like shorting the capacitor so that it will discharged the content via the SCR. Eitherway both the SCR and the damping diode will be force to short out. and one of them will get blown, and unfortunately, D16 gets the short condition first seizing the entire circuit from functioning.

So as to state if it is good to disconnect the ignition coil to the output of the cdi when you try to turn the engine..

the answer: NO so always make sure the ignition coil is connected to the cdi. Avoid cranking the engine without any ignition coil connected, Remember, It is easier to fix IGNITION COIL related problems that CDI one, since the later is an external part of the cdi. Internal part of the ignition controller is not exposed and CDI replacement will be costly.

All credit of the photos goes to Mr. David Cooper of UK. Thank you very much, Cheers mate!

Read more »

The problem was the CDI which is costly refuses to give a spark. All external component that directs to the ignition controller are all good and thus only the cdi was the suspect.The motorcycle was on a restoration process, and only the ignition was the problem. I had asked his permission to post all the photos here for others who has the same problem that may help you just in case.

Of course, in order for you to do so is stripped all of the epoxy resin that covers the whole black box to expose the board which is very tricky and extra care and more patience is needed. All components must be intact to the board or else it will be much harder to determine what component had failed. Servicing a defective Ignition Controller is difficult and have to isolate each and one block from one another.

Through e-mail, he sent me all the photos needed as shown.

|

| Fig. 1 |

|

| Fig. 2 |

|

| Fig. 3 |

|

| Fig. 4 |

|

| Fig. 5 |

|

| Fig. 6 |

|

| Fig. 7 |

By the way, the CDI of CRM250 MD24 is an AC-CDI type, it has an external high voltage exciter coil that charges the capacitor as the engine is turn. This means that the higher the engine rpm, the higher the voltage can be measured at the charging capacitor.

Moving on finding the culprit of the no spark symptoms of this cdi. Test was done trying to find why it refuses to spark at the tip of the spark plug. Figure 6 shows the voltage reading from turning the engine indicates that there is a voltage at the anode pin of the thyristor. This means that the high voltage of the generator is getting inside, indicating a healthy High voltage generator. One pin of the charging capacitor is connected to that cathode pin of the switching thyristor (SCR), hence there will be voltage, but there will be no vltage at the other pin if your reference is ground, since the charge can only be dumped to the ignition coils primary winding, which act as the load when the SCR is triggered by the MCU. If all is good, the charge will then be dumped causing a momentary magnetic field to that winding and transferred it to the secondary winding in a x10 ratio which is enough to create spark at the tip of the spark plug.

And that is where the problem exist. It does not create any spark. Hence, with the existence of voltage across the capacitor.(by the way to see the voltage is being kept by the capacitor before the dump, put the voltage meter probe across the two pins on the charging capacitor. Voltage will remain there up until the SCR is triggered.)

So before the capacitor, the circuit is generally good. but then the output towards the ignition coil output is not. Generally, If you look at all CDI schematic posted all over the internet, there is still a major component after the pin of the charging capacitor..(did u notice it)

|

| Fig 8 |

That DIODE in regards to the CRM250 MD24 photo,was traced and looking at Fig. 5. designated as D16..

And guess what, It is actually shorted. If that is already shorted then the path of the charging capacitor is nearly directs to ground and no charge will be directed to the ignition coil..

In other words, when the damping diode is already shorted, the charge will no longer flow to the ignition coil, and the system is stopped. Seems odd..that is how it works.

Many will think how the damping diode actually get blown. SIMPLE

if the ignition coil is removed from the circuit and tried to turn the engine without it. The diode will then get the ACTUAL charged of the capacitor and dumps it to ground. It is like shorting the capacitor so that it will discharged the content via the SCR. Eitherway both the SCR and the damping diode will be force to short out. and one of them will get blown, and unfortunately, D16 gets the short condition first seizing the entire circuit from functioning.

So as to state if it is good to disconnect the ignition coil to the output of the cdi when you try to turn the engine..

the answer: NO so always make sure the ignition coil is connected to the cdi. Avoid cranking the engine without any ignition coil connected, Remember, It is easier to fix IGNITION COIL related problems that CDI one, since the later is an external part of the cdi. Internal part of the ignition controller is not exposed and CDI replacement will be costly.

All credit of the photos goes to Mr. David Cooper of UK. Thank you very much, Cheers mate!

Kawasaki OEM DC-CDI

Ever wonder whats inside an OEM DC-CDI of kawasaki,

I got time to open up one just for all of my readers, with my step by step on how i did it without messing up the circuitry of the igniter. At first before i opened up this little black box. The Unit is covered with rubber epoxy and sometimes hardened epoxy to avoid malfunction from moist and vibration of the motorcycle.

i tried not to mess up with the casing, unfortunately it didnt work for me, the plastic case is too brittle. slowly i chipped the casing with a diagonal cutter starting from the top cover. After hours doing the case thing. ,

The rubber epoxy will be exposed and time to strip it away so that the components of the board will be visible like this.

I used bamboo stick, (do not use hard pointed objects on clearing this epoxy, we do not know where the components are and might get damage by it)..so better yet use stick. ( i did not use any solvent to strip this...i need the entire board intact and the semiconductors un damage...

Read more »

I got time to open up one just for all of my readers, with my step by step on how i did it without messing up the circuitry of the igniter. At first before i opened up this little black box. The Unit is covered with rubber epoxy and sometimes hardened epoxy to avoid malfunction from moist and vibration of the motorcycle.

i tried not to mess up with the casing, unfortunately it didnt work for me, the plastic case is too brittle. slowly i chipped the casing with a diagonal cutter starting from the top cover. After hours doing the case thing. ,

The rubber epoxy will be exposed and time to strip it away so that the components of the board will be visible like this.

I used bamboo stick, (do not use hard pointed objects on clearing this epoxy, we do not know where the components are and might get damage by it)..so better yet use stick. ( i did not use any solvent to strip this...i need the entire board intact and the semiconductors un damage...

Labels:

CDI,

cdi repair,

DC-CDI,

igniter,

kawasaki igniter,

Shogun

Modifying DC-CDI

Currently working on reverse engineering the DC-CDI of my suzuki motorcycle. I had read almost all articles in regards to capacitive discharge ignition for motorcycle, from analog to the complex MCU based ignition, But this ignition made by denso really making me work hard to find the MCU datasheet but to no avail.

Looking at the picture (click to zoom), The MCU is actually made by freescale inc. a Motorola based MCU with a part number SC528524. The IC is actually a predefined package for the motorcycle manufacturer design, so getting the data out of it will be impossible, not unless you are one of the engineer and designer who actually built the black box.

The SC528524 is the heart of this CDI, it holds the data for generating the ignition map, the timing, the RPM limiter, the TPS switcher, the SCR gate trigger and the control of the High Voltage Converter. If and If only we have the datasheet of the MCU, perhaps we can be able to use the Rx and Tx pins to communicate it with a computer and proper software. But again, since it is a predefined MCU made only for them, reverse engineering with the current MCU is difficult.

And so the only way to use those Rx and Tx port is to remove the heart and replace it with a microcontroller with a UART function.

By tracing each section of the entire block box and redraw the schematic, all possible component of a good working ignition are all there, so by using any other MCU, an open source software may do the trick. How about using PIC Microcontroller made by Microchip, Yes there are lots of them all over the internet, just search them.

Example is the cheap pic16f628A, a programmable MCU nearly being used by ignition enthusiast who design their own version of digital cdi, that by pin to pin connection on the remove motorola MCU. It may actually work.

Photo shown is a very popular ignition made for remote controlled planes, It is an open source project by many people in a forum. Hardware and Firmware for the 16f628A microchip are all posted here...

1. www.transmic.net

2. www.electronics.gompy.net/

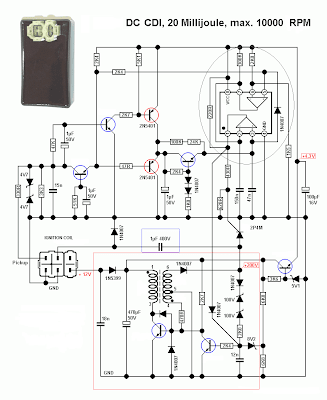

Illustration of A Working DC-CDI

Digital DC-CDI schematic (full schematic diagram of shogun 125cc ignition controller)

The schematic was traced manually using every component attached to the circuit board, and with the help of a schematic capture such as diptrace, it will then be easy to interface the pic16f628A with the original functional block below.

1. Pulse Shaping Block

2. TPS Block

3. MCU block (heart of any digital CDI)

4. SCR/Capacitor block

5. High Voltage converter block (no alternator needed)

Pulse shaping and conditioner block

The circuit inside this block is responsible for the shaping and and clipping for the amplitude for the MCU to receive and access as the flywheel equipped with magnet passes through the pulser coil. Depending on the polarity of the coil, this circuit will receive that pulse every revolution whether positive or negative pulse. If the program of the MCU needs to receive only the negative pulse then this circuit will be responsible for making it a negative pulse if the polarity of the pulser is a positive output, and vice versa.

TPS block circuit

As the name implies. TPS corresponds to Throttle Positioning Sensor. This sense the throttle position by way of a switch fitted on the carburetor mainly, for improve acceleration purposes and or fuel efficiency delivery of the whole ignition front end. Not all CDI is equipped with such for a cdi can work with or without the TPS. But for an EFI system, TPS is a must. (but it will not covered with this article for the CDI being modified here is mainly for carbureted type ignition)

MCU block

The heart and source of all sensor and outputs the necessary command to the SCR, HV generator oscillator, and TPS input, as well as the pulser coil input. Depending on the firmware itself will make every cdi differs in performance and output. The stored ignition mapping will also tell the difference where the bike will pull hard at an RPM band. All CDI are created equal, only the ignition map differs. So why in the heck did they make such racing CDI if they are almost equal with the standard CDI. Theoretically, only the power on the certain RPM band will be moved, it will not grant you extra HP for a normal engine. If the engineers were able to get 50 reliable HP, they would have done it... but you can modify the distribution of the power. (Ex: more advance = more torque at a particular powerband) or remove the rev limiter that limits the probability of having above optimum performance.Concretely, to tune the advance curve according to the engine/exhaust/carburation/air filter and to get same extra HP, a real dynamometer will serve you as the basis of engine tuning, and not on the CDI alone.

SCR/Capacitor block

This is the area on when to charge and then discharge the capacitor the dump to the ignition coil. As the capacitor is charge by the HV converter, when the MCU sense the first pulse, it will then calculate everything via the ignition map stored on the MCU, either advance or retard, then trigger the scr gate at the right time..The engine will lose power when the CDI block fired the spark plug at the wrong timing due to wrong calculation and data of the MCU. so all in all, this block still rely on the MCU data.

High Voltage Converter Block

An important block for an ignition to be called DC-CDI. The circuit that is responsible of producing a large amount of voltage from 20kv up to 40kv, but of course depending on the design and topology used in this converter, the efficiency and reliability is important. Instead of having an external High voltage generator located in the generator side to which an AC-CDI use, DC-CDI do not have that kind of winding, instead it is placed inside the black box. An ocillator that is connected to the MCU SCR trigger output is needed to off and on the HV converter for charging and discharging the Capacitor and in sync with the SCR gate triggering to avoid the gate locking down during discharge. There are many design employed on a HV converter of dc-cdi, such as flyback converter, push pull converter, and the cheap low cost forward converter. In the circuitry above, they used the forward converter, only few components needed to have a cheap but reliable kind of converter for the CDI, although the efficiency is not that high in comparison with the flyback topology converter,

To be continued..for the placing of the pic16f628A and preliminary testing on the workbench before trying it on the bike,and communication with PC to update and change ignition map...Please be back thank you.

Read more »

Looking at the picture (click to zoom), The MCU is actually made by freescale inc. a Motorola based MCU with a part number SC528524. The IC is actually a predefined package for the motorcycle manufacturer design, so getting the data out of it will be impossible, not unless you are one of the engineer and designer who actually built the black box.

The SC528524 is the heart of this CDI, it holds the data for generating the ignition map, the timing, the RPM limiter, the TPS switcher, the SCR gate trigger and the control of the High Voltage Converter. If and If only we have the datasheet of the MCU, perhaps we can be able to use the Rx and Tx pins to communicate it with a computer and proper software. But again, since it is a predefined MCU made only for them, reverse engineering with the current MCU is difficult.

|

| Shogun DC-CDI MCU removed |

By tracing each section of the entire block box and redraw the schematic, all possible component of a good working ignition are all there, so by using any other MCU, an open source software may do the trick. How about using PIC Microcontroller made by Microchip, Yes there are lots of them all over the internet, just search them.

|

| pic16f628A by microchip |

Photo shown is a very popular ignition made for remote controlled planes, It is an open source project by many people in a forum. Hardware and Firmware for the 16f628A microchip are all posted here...

1. www.transmic.net

2. www.electronics.gompy.net/

Illustration of A Working DC-CDI

Digital DC-CDI schematic (full schematic diagram of shogun 125cc ignition controller)

|

| Full schematic diagram of Suzuki Shogun DC-CDI |

1. Pulse Shaping Block

2. TPS Block

3. MCU block (heart of any digital CDI)

4. SCR/Capacitor block

5. High Voltage converter block (no alternator needed)

Pulse shaping and conditioner block

The circuit inside this block is responsible for the shaping and and clipping for the amplitude for the MCU to receive and access as the flywheel equipped with magnet passes through the pulser coil. Depending on the polarity of the coil, this circuit will receive that pulse every revolution whether positive or negative pulse. If the program of the MCU needs to receive only the negative pulse then this circuit will be responsible for making it a negative pulse if the polarity of the pulser is a positive output, and vice versa.

TPS block circuit

As the name implies. TPS corresponds to Throttle Positioning Sensor. This sense the throttle position by way of a switch fitted on the carburetor mainly, for improve acceleration purposes and or fuel efficiency delivery of the whole ignition front end. Not all CDI is equipped with such for a cdi can work with or without the TPS. But for an EFI system, TPS is a must. (but it will not covered with this article for the CDI being modified here is mainly for carbureted type ignition)

MCU block

The heart and source of all sensor and outputs the necessary command to the SCR, HV generator oscillator, and TPS input, as well as the pulser coil input. Depending on the firmware itself will make every cdi differs in performance and output. The stored ignition mapping will also tell the difference where the bike will pull hard at an RPM band. All CDI are created equal, only the ignition map differs. So why in the heck did they make such racing CDI if they are almost equal with the standard CDI. Theoretically, only the power on the certain RPM band will be moved, it will not grant you extra HP for a normal engine. If the engineers were able to get 50 reliable HP, they would have done it... but you can modify the distribution of the power. (Ex: more advance = more torque at a particular powerband) or remove the rev limiter that limits the probability of having above optimum performance.Concretely, to tune the advance curve according to the engine/exhaust/carburation/air filter and to get same extra HP, a real dynamometer will serve you as the basis of engine tuning, and not on the CDI alone.

SCR/Capacitor block

This is the area on when to charge and then discharge the capacitor the dump to the ignition coil. As the capacitor is charge by the HV converter, when the MCU sense the first pulse, it will then calculate everything via the ignition map stored on the MCU, either advance or retard, then trigger the scr gate at the right time..The engine will lose power when the CDI block fired the spark plug at the wrong timing due to wrong calculation and data of the MCU. so all in all, this block still rely on the MCU data.

High Voltage Converter Block

An important block for an ignition to be called DC-CDI. The circuit that is responsible of producing a large amount of voltage from 20kv up to 40kv, but of course depending on the design and topology used in this converter, the efficiency and reliability is important. Instead of having an external High voltage generator located in the generator side to which an AC-CDI use, DC-CDI do not have that kind of winding, instead it is placed inside the black box. An ocillator that is connected to the MCU SCR trigger output is needed to off and on the HV converter for charging and discharging the Capacitor and in sync with the SCR gate triggering to avoid the gate locking down during discharge. There are many design employed on a HV converter of dc-cdi, such as flyback converter, push pull converter, and the cheap low cost forward converter. In the circuitry above, they used the forward converter, only few components needed to have a cheap but reliable kind of converter for the CDI, although the efficiency is not that high in comparison with the flyback topology converter,

To be continued..for the placing of the pic16f628A and preliminary testing on the workbench before trying it on the bike,and communication with PC to update and change ignition map...Please be back thank you.

5 pin AC-CDI

Schematic diagram of a common 5 pins AC-CDI use on some commuter and small bikes. almost all CDI uses the same approach but with different type of component used for the application and or model of the bike. 5 pin AC-CDI differs from those 4 pin with the addition of the kill switch to stop the engine when ignition is turn OFF.

Read more »

Yamaha DT125 CDI

This is the diagram of a china replica CDI (capacitive discharge ignition) of Yamaha DT125 2 stroke machine. The circuit can be used on other existing AC-cdi motorcycle, as long as there is a high voltage generator on the stator.

Read more »

HTML Comment Box is loading comments...

AC-CDI

Inside an AC-CDI of a GY6 50cc-125cc engine. An AC-CDI is a type of ignition wherein it can be operated without a battery installed on a bike but needing a HIGH VOLTAGE GENERATOR that will charge the capacitor inside the cdi to discharge tthrough your ignition coil producing spark at the spark plug unlike, dc-cd wherein no HV generator is necessary for they have a built in converter inside.

The circuit below is from a gy6 based engine. it incorporate a pulse shaping circuit, unlike the cdi of yamaha DT125 posted here Yamaha DT125 cdi.

for more ac cdi circuits and schematic diagram click here

More Ac-cdi schematic for you...

Read more »

The circuit below is from a gy6 based engine. it incorporate a pulse shaping circuit, unlike the cdi of yamaha DT125 posted here Yamaha DT125 cdi.

for more ac cdi circuits and schematic diagram click here

More Ac-cdi schematic for you...

DC-CDI schematic (updated)

DC-CDI counterpart of AC-CDI is an ignition analog or digital that uses low voltage external power supply to work. the difference AC-CDI needs external High Voltage COIL no battery configuration whereas DC-CDI needs a battery without HV COIL.

Looking at the picture on the left, it is a complete schematic diagram of a dc-cdi. Its a 4-pin system, comprising pick-up input, battery +12 volts in, Gnd, and Ignition coil out pins. There is no High Voltage input pin like those of AC-CDI. If it will be differentiated with the AC-CDI here, you will notice theres a transformer diagram on this schematic.The circuit on the RED BOX comprises the internal High Voltage generator of a DC-CDI, where the 12 volts battery in will be converted to 200-400 volts depending on the design of the inverter. This design uses two transistor dc-ac converter with external on/off circuit to charge and discharge the capacitor BLUE BOX via SCR. the HV converter is controlled by the circuit on GRAY box, that as soon as the pulse conditioning circuit sense the pick-up coil will send triggering signal on both SCR and HV oscillator respectively to turn them on and off at the right time.

CDI or Capacitor Discharge Ignition, from the name itself, capacitor is very critical during its operation, must handle charge and discharge time as well as heat being generated by the whole circuit inside the block box, that is why manufacturer uses special capacitors specifically made for ignitions, and not just like those mylar capacitor found on some electronic circuits. They are rated 400 to 630 volts. ranging from .47uf up to 2.2uf. Value is also so critical in every applications and designs. In this circuit, they use 1uf / 400 volts with HV out of 200 volts will equals to 20 mj.

Read more »

|

| DC-CDI schematic diagram |

Looking at the picture on the left, it is a complete schematic diagram of a dc-cdi. Its a 4-pin system, comprising pick-up input, battery +12 volts in, Gnd, and Ignition coil out pins. There is no High Voltage input pin like those of AC-CDI. If it will be differentiated with the AC-CDI here, you will notice theres a transformer diagram on this schematic.The circuit on the RED BOX comprises the internal High Voltage generator of a DC-CDI, where the 12 volts battery in will be converted to 200-400 volts depending on the design of the inverter. This design uses two transistor dc-ac converter with external on/off circuit to charge and discharge the capacitor BLUE BOX via SCR. the HV converter is controlled by the circuit on GRAY box, that as soon as the pulse conditioning circuit sense the pick-up coil will send triggering signal on both SCR and HV oscillator respectively to turn them on and off at the right time.

CDI or Capacitor Discharge Ignition, from the name itself, capacitor is very critical during its operation, must handle charge and discharge time as well as heat being generated by the whole circuit inside the block box, that is why manufacturer uses special capacitors specifically made for ignitions, and not just like those mylar capacitor found on some electronic circuits. They are rated 400 to 630 volts. ranging from .47uf up to 2.2uf. Value is also so critical in every applications and designs. In this circuit, they use 1uf / 400 volts with HV out of 200 volts will equals to 20 mj.

CDI Building Blocks

This article will cover how motorcycle capacitive discharge ignition works, its building blocks. How an AC-CDI can be made a DC-CDI, how the internal dc-dc converter of a dc-cdi affects the overall performance. First. we will cover the AC-cdi to which some scooters, moped, and some chinese made 2 wheels utilize. Looking at the picture, it covers the building block of an AC-CDI,

it can easily be distinguished on any bike because they have the so called KILL switch to where it will disable the switching of the SCR or to cut the high voltage generator on supplying the capacitor to off the engine. Kill switch is a must for any ac-cdi circuit, and without it, the exciter or source coil will continue to rotate and supply high voltage to the capacitor.

AC-CDI can be made by enthusiast whether they are analog to digital, from simple to complex form, from fixed to a programmable to where you can adjust the ignition curve to meet your needs on racing or street driveability. Here we will not gather any information about racing CDI, for they are almost the same to what our bike is using, in short, they are only the modified version and sometimes, (this is not a fact but sometimes it is true) that they perform worse than those OEM fitted on our factory bikes, again but not all.

ANALOG AC-CDI

The simplest form of cdi which compose of discrete components, like resistor, capacitor, transistor, an scr and diodes.

Here shown in the picture is an analog simple easy to build cdi. It has no advance function, the trigger of the scr is straight forward.

When pulses from the pick-up coil is sensed, it will produce voltage near but not more than 5volts. It will then be configure by D3 for positive pulse, and condition by the R2 and C2 for noise removal of the pick-up coil for SCR Q1 gate triggering.

Exciter or source coil will produce 60-120 volts, this depends on the power of the coil, is then converted by D1 to DC for C1 charging..

When the pulse arrived at SCR gate, it will be triggered and shunting the capacitor charge to ground and dumped it on the ignition coil, and because ignition coil is just a straight forward step up transformer, primary will then produce magnetic field transferring power to secondary winding and because of the ratio between the two windings about 1:100, secondary will produce a brief 20,000kv - 30,000kv then onto the ignition wire, then finally at the tip of the spark plug gap to produce an ARC.

DIGITAL AC-CDI

On the other hand, a digital AC-CDI form the name itself, compose of perhaps some digital ic like, microprocessors to where configuration of advance thru PC is probable. some uses micros like PIC, AVR, freescale, and the likes. example of this can be found from site like

http://sportdevices.com/ignition/ignition.htm

Comparing to the simple analog AC-CDI posted above, the triggering circuit before the gate of the SCR went from the microcontroller pic16f84A to which must be programmed according to the specification of your motorbike, I'll not tell you exactly how this circuit works, for all of the data are within their site.

This circuit can operate with or without battery but nonetheless, since microcontroller IC needs constant supply, it may be best to use a battery to avoid failure.

Again, there is the STOP engine button connected to the gate of the scr via ground to of course stop the engine.

The microcontroller do all the stuff for pulse conditioning, as well as retarding or advancing the ignition to make room for a configurable driveability of your motorbike.

AC-CDI , can be configured to work as a DC-CDI with the help of a high voltage dc-dc converter in replacement for the high voltage generator coil that supply the necessary voltage to charge the capacitor, and the more complex yet very effective dc-cdi comes to play.

DC-CDI

Here a block diagram of this kind of ignition controller found nowadays on motorbike, the exciter coil, or source coil, or high voltage generator coil is omitted. but then a battery is in placed to power up the cdi. KILL switch is also omitted for once the power supply coming in from the battery is cut, there is no more power for the internal high voltage converter to use hence cutting of any means of charging the capacitor turning off the engine.

Only difference of the DC to AC type, here there will be a more complex circuit composed of the high voltage dc-dc converter that will act as the exciter coil or source coil. I will take this dc-cdi schematic for example.

The circuit on the red block is the source of the high voltage and act as the source coil of an AC-CDI system. Its a free running oscillator, but unlike the exciter coil produces continuous voltage, HV converter must be turned off in relation to the triggering of the SCR switch. This is not to cause a shorted path when the SCR dumps the charge of the capacitor. They are timely tied together.

Depending on the frequency of the oscillator, this has a big effect on how fast it can charge the capacitor at higher revolution of the engine. This circuit sometimes limit the overall performance of any Capacitor Discharge ignition built. If they can be made to be more powerful then we may be able to have a higher performance cdi as what those so called racing cdi does. but we all know that having a powerful ignition output means more voltage is needed thus more current consumption on the battery. Other's often states that changing the charging capacitor to a higher value compensate for this trade off,

"As the size of the capacitor is increased, the output of the ignition also increases, however the oscillator must be made more powerful. Certain trade offs must be made in design for a particular application."

still without improving the High voltage converter circuit, ignition limitations is in place.

There are many variations of the HIGH VOLTAGE CONVERTER used on a dc-cdi, other uses the typical low cost forward converter type some uses the switching mode type with onboard IC like SG3525, UC3845, other use microcontroller to switch it on and off. There are too many variation of producing high voltage for this kind of ignition. The trade-off is actually the design, the size and the frequency of the oscillator to charge the capacitor at a faster time.

I am into currently modifying this OEM dc-cdi of my motorbike by replacing its onboard converter to a more powerful one posted here

suzuki-shogun-oem-dc-cdi

and will try to use this kind of high voltage converter schematic

I am into modifying for a smaller pcb for this so that i can put it right on top of the original dc-cdi board. This high voltage can be configured by modifying the feedback control resistors R2 and R3.

Read more »

it can easily be distinguished on any bike because they have the so called KILL switch to where it will disable the switching of the SCR or to cut the high voltage generator on supplying the capacitor to off the engine. Kill switch is a must for any ac-cdi circuit, and without it, the exciter or source coil will continue to rotate and supply high voltage to the capacitor.

AC-CDI can be made by enthusiast whether they are analog to digital, from simple to complex form, from fixed to a programmable to where you can adjust the ignition curve to meet your needs on racing or street driveability. Here we will not gather any information about racing CDI, for they are almost the same to what our bike is using, in short, they are only the modified version and sometimes, (this is not a fact but sometimes it is true) that they perform worse than those OEM fitted on our factory bikes, again but not all.

ANALOG AC-CDI

The simplest form of cdi which compose of discrete components, like resistor, capacitor, transistor, an scr and diodes.

Here shown in the picture is an analog simple easy to build cdi. It has no advance function, the trigger of the scr is straight forward.

When pulses from the pick-up coil is sensed, it will produce voltage near but not more than 5volts. It will then be configure by D3 for positive pulse, and condition by the R2 and C2 for noise removal of the pick-up coil for SCR Q1 gate triggering.

Exciter or source coil will produce 60-120 volts, this depends on the power of the coil, is then converted by D1 to DC for C1 charging..

When the pulse arrived at SCR gate, it will be triggered and shunting the capacitor charge to ground and dumped it on the ignition coil, and because ignition coil is just a straight forward step up transformer, primary will then produce magnetic field transferring power to secondary winding and because of the ratio between the two windings about 1:100, secondary will produce a brief 20,000kv - 30,000kv then onto the ignition wire, then finally at the tip of the spark plug gap to produce an ARC.

DIGITAL AC-CDI

On the other hand, a digital AC-CDI form the name itself, compose of perhaps some digital ic like, microprocessors to where configuration of advance thru PC is probable. some uses micros like PIC, AVR, freescale, and the likes. example of this can be found from site like

http://sportdevices.com/ignition/ignition.htm

|

| PICTURE property of SPORTDEVICES.COM |

This circuit can operate with or without battery but nonetheless, since microcontroller IC needs constant supply, it may be best to use a battery to avoid failure.

Again, there is the STOP engine button connected to the gate of the scr via ground to of course stop the engine.

The microcontroller do all the stuff for pulse conditioning, as well as retarding or advancing the ignition to make room for a configurable driveability of your motorbike.

AC-CDI , can be configured to work as a DC-CDI with the help of a high voltage dc-dc converter in replacement for the high voltage generator coil that supply the necessary voltage to charge the capacitor, and the more complex yet very effective dc-cdi comes to play.

DC-CDI

Here a block diagram of this kind of ignition controller found nowadays on motorbike, the exciter coil, or source coil, or high voltage generator coil is omitted. but then a battery is in placed to power up the cdi. KILL switch is also omitted for once the power supply coming in from the battery is cut, there is no more power for the internal high voltage converter to use hence cutting of any means of charging the capacitor turning off the engine.

Only difference of the DC to AC type, here there will be a more complex circuit composed of the high voltage dc-dc converter that will act as the exciter coil or source coil. I will take this dc-cdi schematic for example.

The circuit on the red block is the source of the high voltage and act as the source coil of an AC-CDI system. Its a free running oscillator, but unlike the exciter coil produces continuous voltage, HV converter must be turned off in relation to the triggering of the SCR switch. This is not to cause a shorted path when the SCR dumps the charge of the capacitor. They are timely tied together.

Depending on the frequency of the oscillator, this has a big effect on how fast it can charge the capacitor at higher revolution of the engine. This circuit sometimes limit the overall performance of any Capacitor Discharge ignition built. If they can be made to be more powerful then we may be able to have a higher performance cdi as what those so called racing cdi does. but we all know that having a powerful ignition output means more voltage is needed thus more current consumption on the battery. Other's often states that changing the charging capacitor to a higher value compensate for this trade off,

"As the size of the capacitor is increased, the output of the ignition also increases, however the oscillator must be made more powerful. Certain trade offs must be made in design for a particular application."

still without improving the High voltage converter circuit, ignition limitations is in place.

There are many variations of the HIGH VOLTAGE CONVERTER used on a dc-cdi, other uses the typical low cost forward converter type some uses the switching mode type with onboard IC like SG3525, UC3845, other use microcontroller to switch it on and off. There are too many variation of producing high voltage for this kind of ignition. The trade-off is actually the design, the size and the frequency of the oscillator to charge the capacitor at a faster time.

I am into currently modifying this OEM dc-cdi of my motorbike by replacing its onboard converter to a more powerful one posted here

suzuki-shogun-oem-dc-cdi

and will try to use this kind of high voltage converter schematic

I am into modifying for a smaller pcb for this so that i can put it right on top of the original dc-cdi board. This high voltage can be configured by modifying the feedback control resistors R2 and R3.

Testing Motorcycle CDI Ignition Coil

CD ignition coil is a step up transformer that transform the voltage generated by the internal HV converter of a CDI into 20 to 40kv in order to achieve a spark at the tip of the plug. Do not be mistaken, CDI coil differs from TCI coil, and almost all available Ignition coil has only one purpose, To produce an arc to spark plug inside the combustion. Photo shown are some variants of ignition coil used on AC-CDI and DC-CDI. At top is china made ignition coil derived from a certain pioneer brand bike, center coil came from my GY6 scooter, and the bottom taken from my existing suzuki shogun 125cc commuter bike. The article will tell us the basic test of ignition coil, that is, resistance and inductance test. The benefits of knowing their resistance and inductance will tell us if the coil will be providing enough energy for our ignition beyond optimum level.

Primary winding compose of few turns thus resistance reading will show milliohms reading and almost zero when using ordinary DVM, thus inductance may be a better choice for an instrument to test it, while as the secondary compose of a hundred turns, it is capable of resistance test.

here are the variation of reading of those three mentioned CDI coil above

The primary winding of the China made CD coil is about 34 uh, when i tried to take resistance test on this side, i only gain 0.3 ohms

for the GY6 coil, i got 29 uh still with a resistance of 0.3 ohms

and for my OEM ignition coil (suzuki shogun 125cc coil) got a reading of 66 uh but still with a reading of 0.3 ohms.

I did this test to be able to determine how it will affect my ignition before i tried to test it on board my motorcycle with the exception of my OEM. Yes they will all work since they are made for a CD ignition. and this inductance will primarily affect the transfer of energy towards the secondary winding of the coil.

For the secondary winding basic test, i use the resistance check, for my homemade inductance tester can only reach the 1 mh range.

Secondary resistance of the china made was 5.65 kohms

GY6 secondary winding resistance of 3.00 kohms

and OEM stands at 6.57 kohms

Higher resistance reading of the secondary means more number of turns and may transform it to a higher voltage output when the primary is being switched by the ignition controller, but then the primary winding also has an adverse effect on the secondary winding. Only by using HIGH voltage tester, we can assure of the reading, but because ignition coil are HIGHLY shield by epoxy resin, we cannot determine if the theory is in fact true that the more number of turns and higher resistance reading will produce more hotter spark.

Soon i will try to make an IGNITION COIL tester to see how the spark is generated by this three outside the combustion..

but then what we will see outside will differ if its inside due the pressure of the combustion. as of now resistance and inductance test is highly recommended for those who wants to try out different CDI coil available.

I am using by the way the china made coil, rather than my SHOGUN OEM, for a change. :-)

Read more »

Primary winding compose of few turns thus resistance reading will show milliohms reading and almost zero when using ordinary DVM, thus inductance may be a better choice for an instrument to test it, while as the secondary compose of a hundred turns, it is capable of resistance test.

here are the variation of reading of those three mentioned CDI coil above

The primary winding of the China made CD coil is about 34 uh, when i tried to take resistance test on this side, i only gain 0.3 ohms

for the GY6 coil, i got 29 uh still with a resistance of 0.3 ohms

and for my OEM ignition coil (suzuki shogun 125cc coil) got a reading of 66 uh but still with a reading of 0.3 ohms.

I did this test to be able to determine how it will affect my ignition before i tried to test it on board my motorcycle with the exception of my OEM. Yes they will all work since they are made for a CD ignition. and this inductance will primarily affect the transfer of energy towards the secondary winding of the coil.

For the secondary winding basic test, i use the resistance check, for my homemade inductance tester can only reach the 1 mh range.

Secondary resistance of the china made was 5.65 kohms

GY6 secondary winding resistance of 3.00 kohms

and OEM stands at 6.57 kohms

Higher resistance reading of the secondary means more number of turns and may transform it to a higher voltage output when the primary is being switched by the ignition controller, but then the primary winding also has an adverse effect on the secondary winding. Only by using HIGH voltage tester, we can assure of the reading, but because ignition coil are HIGHLY shield by epoxy resin, we cannot determine if the theory is in fact true that the more number of turns and higher resistance reading will produce more hotter spark.

Soon i will try to make an IGNITION COIL tester to see how the spark is generated by this three outside the combustion..

but then what we will see outside will differ if its inside due the pressure of the combustion. as of now resistance and inductance test is highly recommended for those who wants to try out different CDI coil available.

I am using by the way the china made coil, rather than my SHOGUN OEM, for a change. :-)

Subscribe to:

Posts (Atom)