Showing posts with label maintenance. Show all posts

Showing posts with label maintenance. Show all posts

Tuesday, October 20, 2015

Shogun Speedometer Panel

Let us take a look inside the speedometer panel of a suzuki shogun 125cc, as shown on the left with speedometer pointer and lcd remove. The main controller of this panel is a chip made by fujitsu with part number MB89943 which is an 8-bit cpu, controlling everything from the movement of the speedometer needle, lcd display. and counter. Data then are stored like odometer, speedometer reset, fuel gauge calibration on the a microwire bus eeprom with part number L46R.

Shogun 125cc user espescially those 2006 model and below experiencing odometer stuck up to 99,999.9 and uncapable of resetting itself back to zero..unfortunately newer model already have its own data stored on the eeprom that resets the odometer after reaching the said value.

The only solution to this problem is to inject the new data stored on newer speedometer panel eeprom to IC5 (L46R) by using an eeprom programmer like IC prog with interface such as tait serial programmer and or JDM programmer.

Lowering Front Shocks

Lowering front suspension on motorcycles offers ride height improvement and drive ability, but this depends on how we approach to do it. Some uses the slipping method in where the telescopic tube is adjusted from the locking nut of the T-post as shown, I just really dont know how secure this approach, because of the tube may slip from time due to heavy bumps on the road. If you will analyze the tube, there is a groove

for the first bolt to secure the telscopic tube not to slip off in its place. That is what the groove stands for. To lower the fork the right way, we need to understand what makes up the front fork, how they work, what components that makes the whole front suspensions.

By dismantling it although i have troubles removing the damping rod bolt at the end of the fork looks like this part by part. CONTINUE reading........

Read more »

for the first bolt to secure the telscopic tube not to slip off in its place. That is what the groove stands for. To lower the fork the right way, we need to understand what makes up the front fork, how they work, what components that makes the whole front suspensions.

By dismantling it although i have troubles removing the damping rod bolt at the end of the fork looks like this part by part. CONTINUE reading........

Installing HAZARD switch

Some bike models especially those commuter bikes often do not have a hazard switch to alert other motorist that you are travelling the road with problem with your bike.

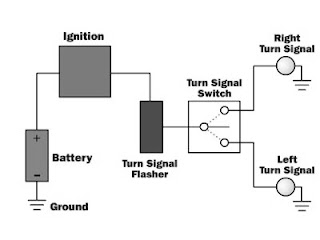

Photo shown is the common block diagram of a turn signal wiring, wherein, when turn signal switch is activated, it will blink the turn signal lights left or right depending on the position of the switch. Front and rear signal lights are just parallel on each side.

More often, riders needs and want to install a HAZARD switch so that when activated will flash all signal lights to alert or inform other motorist to take caution on following you, that maybe you have some sorth of problem and or you are on a convoy.

HAZARD switch is so easy to do if you just follow your own bikes wiring diagram, by taking the common block diagram above only four components will be installed to have a hazard signal function.

Read more »

Photo shown is the common block diagram of a turn signal wiring, wherein, when turn signal switch is activated, it will blink the turn signal lights left or right depending on the position of the switch. Front and rear signal lights are just parallel on each side.

More often, riders needs and want to install a HAZARD switch so that when activated will flash all signal lights to alert or inform other motorist to take caution on following you, that maybe you have some sorth of problem and or you are on a convoy.

HAZARD switch is so easy to do if you just follow your own bikes wiring diagram, by taking the common block diagram above only four components will be installed to have a hazard signal function.

- normally open push button switch

- 2 pcs of rectifier diode (ex: 1n4002)

- 3 pcs of stranded wire, prefer #18 AWG

- and an electronic flasher like on this link universal led flasher for leds or bulbs

Hazard Switch connection

The turn signal flasher on the block diagram will be replaced by your electronic flasher, aftermarket and or the DIY mentioned, and just follow the add on components, and voila, you have now a hazard function. no need for rewiring your old system.

Oil Drain Plug Thread fix

Been quite a while not having to share with works i've done with my shogun..until up recently i have troubles with one of my drain plug getting loose after my change oil routine. Many times, as far as i know, this area of the engine is prone to loosing thread with the removal of the bolt and during the tightening series, and other's only solution was to OVERSIZE it to the next allowable range just to have it fix, then so on and so forth..what if it get loose again, This i dont like to know.

Aluminum is so prone to this problem, especially when the engine is cold. I usually change my oil during morning after firing the engine for 5 minutes, but then i forgot this routine then this what happens.

Anyway, this is my way of fixing my loose drain plug..

The picture shows how the thread was badly worn,

Read more »

Aluminum is so prone to this problem, especially when the engine is cold. I usually change my oil during morning after firing the engine for 5 minutes, but then i forgot this routine then this what happens.

Anyway, this is my way of fixing my loose drain plug..

The picture shows how the thread was badly worn,

Wave 125 S Panel Repair

Recently, a friend of mine is asking if i can repair his Honda Wave 125 S speedometer panel that is not functioning. No power, no activity. I said of course. so he handed it to me, and test. Before i opened the said panel, i needed to have a wiring diagram of the model, and here it is.

Although the picture seems blurred when i got it from a site, the color coding is enough for me to know which is the positive and negative line of the supply so that i can power up the board without having is entire bike, and so i powered the panel...NOTHING...no activity.

My first visual inspection on the parts, i found out that one of the transistor at the regulator part have BLACK marks on its solder...it means it was burnt by a mistake somewhere by the owner on its motorcycle wiring that causes the panel to FAIL..

If you can see it on the picture TR102 solder, has a BLACK mark, so i immediately test it with my digital diode tester, Im not surprise of the outcome, there..the transistor pins are all shorted. in all probe points.

Read more »

Although the picture seems blurred when i got it from a site, the color coding is enough for me to know which is the positive and negative line of the supply so that i can power up the board without having is entire bike, and so i powered the panel...NOTHING...no activity.

My first visual inspection on the parts, i found out that one of the transistor at the regulator part have BLACK marks on its solder...it means it was burnt by a mistake somewhere by the owner on its motorcycle wiring that causes the panel to FAIL..

If you can see it on the picture TR102 solder, has a BLACK mark, so i immediately test it with my digital diode tester, Im not surprise of the outcome, there..the transistor pins are all shorted. in all probe points.

Motorcycle Gear Position Sensor

Ever wonder how a gear position sensor of small bikes look like, photo shown is where it is located. This sensor from a Suzuki Shogun 125cc is located near the front sprocket, the transmission shift of this bike is 1 down 3 up with neutral in the middle of 1st gear and 2nd gear.

After removing the two screws that hold the sensor on the engine, upon pulling out, you will notice the contact with 4 big circle and 1 small which is the neutral, it works actually by contacting it with ground.

This is how it looks like after the sensor is remove, notice the single PIN which rotates in accordance with the selected gear and will contact with the dot on the sensor. it can be remove to adjust the tension of the spring to make it stiffer and allow it to contact more with the switch, if u have problems of intermittent like i do this is where the problem exist and not with-in your panel indicators.

Read more »

After removing the two screws that hold the sensor on the engine, upon pulling out, you will notice the contact with 4 big circle and 1 small which is the neutral, it works actually by contacting it with ground.

This is how it looks like after the sensor is remove, notice the single PIN which rotates in accordance with the selected gear and will contact with the dot on the sensor. it can be remove to adjust the tension of the spring to make it stiffer and allow it to contact more with the switch, if u have problems of intermittent like i do this is where the problem exist and not with-in your panel indicators.

Spark Plug Cap Resistor

I recently encountered another problem with my suzuki ignition, that even if i am kicking the hell on the kick starter wont even nudge or start my bike. Ever since i added this ignition-wire-ground-strap , it became a tester of some sort due to the spark jumping on that shield ground, that from there it is telling me, the PLUG CAP resistor is too corroded to accept even an arc to feed the spark plug GAP. It has been three times i replaced my plug cap. so in the end, instead of buying the same crap, i made a minor modification using that plug cap and a resistor of 2.2k used in every electronic circuits.

Shogun Clutch Spring and lining

Sliding clutch, delay of power, fuel consumption up. This are some of the reason the CLUTCH system of your shogun must be inspected, and in need of repairs.

This photo shows the internals of the right side crankcase cover of a manual transmission shogun. The release plate cover of the clutch spring has been removed to expose the 4 clutch spring, In order to remove the plate, you'll be needing the close wrench #10, two of them actually in order to counter the rotation of the clutch system when dismantling the release plate.

This is a closer view of the clutch spring, An OEM parts is fitted here, but there are other alternatives out in the market that differs in stiffness like KITTI racing clutch spring, as shown kitti

Making the clutch spring more stiff means extra performance on clutch grip thus improving torque and power but with the expense the life of your lining.

Other motorcycle enthusiast actually trying to replace 2 of the 4 spring with stiff ones to improve clutch grip with less effort on pressing the clutch lever, What they didnt know, it deformes the release plate and have an un even wear on the lining...Its better to replace 4 rather than two.

Shogun FL125 Generator Test

Shogun FL125 charging system is actually the same as shogun FD125XRM. This article will show you how to test your electrical preferably the CHARGING and lighting system.

CHARGING and LIGHTING wiring diagram

Here i'll be giving you where and what to check if you are having problems with battery charging and lighting problems. You'll be needing a multi meter a digital with a diode test to perform troubleshooting your own bike.

LOCATION of SHOGUN FL125 Regulator

The regulator is located in front when you take off front cover, shown in number 2 with part number SH672, remove the connector shown in number 1, set your multimeter to diode test and follow the next picture for the right data.

You dont need to turn your ignition, this is to test the leakage on your Regulator.

The reading of all the test must be close to what is written above, if there is a short or almost 0 on the digital read out then the Regulator is defective.

If all test of the regulator is OK!! we then proceed with the generator system and lighting coils resistance and voltage.

GENERATOR Resistance and Voltage check

Set the digital multimeter in resistance range.

Disconnect the black connector as shown to perform resistance and voltage check, this is the connector of the generator, other is for the pick-up coil and ground.

for lighting coil resistance, connect the multimeter probe to Y/W (yellow with white strip wire) and to ground..

The reading must be

0.4 - 1.0 ohms

and for the charging coil, connect probe to W/R (white wire with red strip) and ground.

The value must be

0.6 - 1.2 ohms

VOLTAGE CHECK

NOTE:

This check must be taken with safety because we are talking about AC voltages here. No wires from the generator must not touch any metal on the chassis. Youll be needing to crank the engine and rev to 5000 rpm to test the generator output.

Multimeter is set to AC voltage range. connect probes as shown, AC do not have polarity so either way..

W/R and ground rev at 5000 rpm must read

50 volts AC or more but no more than 100 volts

Y/W and ground rev at 5000 rpm should read

40 volts AC or more but not more than 80 volts

readings not close or lower than the specified value means there are problems with the generator windings, either there are short due to exposed wires inside and or the skin coating of the enamel wires of the windings are already exposed to the oil.

GOODLUCK with the test.

UPDATED

Full schematic wiring diagram of this bike can be found here

SHOGUN COMPLETE WIRING DIAGRAM

Read more »

CHARGING and LIGHTING wiring diagram

Here i'll be giving you where and what to check if you are having problems with battery charging and lighting problems. You'll be needing a multi meter a digital with a diode test to perform troubleshooting your own bike.

LOCATION of SHOGUN FL125 Regulator

The regulator is located in front when you take off front cover, shown in number 2 with part number SH672, remove the connector shown in number 1, set your multimeter to diode test and follow the next picture for the right data.

You dont need to turn your ignition, this is to test the leakage on your Regulator.

The reading of all the test must be close to what is written above, if there is a short or almost 0 on the digital read out then the Regulator is defective.

If all test of the regulator is OK!! we then proceed with the generator system and lighting coils resistance and voltage.

GENERATOR Resistance and Voltage check

Set the digital multimeter in resistance range.

Disconnect the black connector as shown to perform resistance and voltage check, this is the connector of the generator, other is for the pick-up coil and ground.

for lighting coil resistance, connect the multimeter probe to Y/W (yellow with white strip wire) and to ground..

The reading must be

0.4 - 1.0 ohms

and for the charging coil, connect probe to W/R (white wire with red strip) and ground.

The value must be

0.6 - 1.2 ohms

VOLTAGE CHECK

NOTE:

This check must be taken with safety because we are talking about AC voltages here. No wires from the generator must not touch any metal on the chassis. Youll be needing to crank the engine and rev to 5000 rpm to test the generator output.

Multimeter is set to AC voltage range. connect probes as shown, AC do not have polarity so either way..

W/R and ground rev at 5000 rpm must read

50 volts AC or more but no more than 100 volts

Y/W and ground rev at 5000 rpm should read

40 volts AC or more but not more than 80 volts

readings not close or lower than the specified value means there are problems with the generator windings, either there are short due to exposed wires inside and or the skin coating of the enamel wires of the windings are already exposed to the oil.

GOODLUCK with the test.

UPDATED

Full schematic wiring diagram of this bike can be found here

SHOGUN COMPLETE WIRING DIAGRAM

Headlight Booster

Want to have more juice out of your stock headlight bulbs? Headlights that are often connected to stator are not too bright that the intensity varies on a designated RPM as such like in suzuki shogun commuter bike wherein at 5000 rpm, the full brightness of the headlight can be attained. The photo below are the before and after in sequence at the same rpm reading of 5000 rpm.

The brighter of the two already have the enhancer. How in the world i did it? considering your headlight attached to your voltage regulator to where it clips the voltage to a desirable level not to break the filament of the bulb by excessive voltage the stator is generating. The higher the Rpm of the engine, the higher the voltage it will generate, and without the voltage regulator, the BULB will instantly get busted.

Read more »

Ignition Wire Ground Strap

Ignition coil at the very least are the last part of any ignition that provide High Voltage for the spark plug to ignite the mixture inside any combustion of an engine, and sometimes the least to overlook when it comes to enhancement. If we analyze our ignition coil, and the parts that covered here are, ignition coil connected to an ignition wire down to spark plug cap to where the spark plug will be connected. But, if we enhanced further our analysis on the said part, only the HV path is directly connected to each component, and the ground is left on where the coil is bolted, then down to the engine itself via the connection of the engine to the chassis, to where the cylinder head with the spark plug ground is then connected and bolt on to receive the ground.

I have been reading all through the net about ground strapping the entire ignition wire in order for the whole system have its own grounding strap instead of relying on the engine chassis ground to i think produce a consistent END part of the ignition to make it more reliable. So why not give a try.

Here what we are going to do is, Adding a direct ground connection on the ignition coil ground down to the cylinder head to where the spark plug is bolted and rely on the engine chassis ground. Materials needed are the following.

Ground strap---this can be found on some computer cables, like the VGA cable, Parallel port cable, etc etc.

We need to remove the other wires inside this ground strap, so that it can be inserted on the ignition wire.

after the removal of all wires being covered with the ground strap, we are ready to insert this strap on the ignition wire.

After minutes of inserting the ground strap must look like this, end to end of the ignition wire must be covered leaving some and twisted at the end for the mounting eyelet to be soldered..The eyelet will be the part to be bolted on the ignition mounting bracket and to anywhere in the cylinder head.

To protect the ground strap from dust, water and any forms of road debris, we need something to hold of also in its place and SHRINK tubing is i think the best for this job. It can be bought at any electronic supply parts nationwide.

This is the final modification of the entire ignition coil, with ignition wire ground strap in place and the eyelet soldered at each end.

Ignition coil bolted to its mounting bracket together with the modded ignition wire ground strap together.

Spark plug cap end with ground connected near the spark plug..

Many people will try to ask,

1.What will be GAINED on doing this kind of MODIFICATION or trick?

ANS: I myself was amazed of doing this kind of mod from a site i recently saw, and logically thinking, why not, thinking outide the box, why the ignition end do not have a proper ground strap and just rely on the engine chassis, and making this mod really make sense that instead of the usual way, why not directly connect such ground as well as ground strapping the entire ignition wire to block any unwanted interference that might affect ignition.

TEST your bike after this mod, if you felt your throttle much crispier than before without this modification, there its a success, for thats why i felt.

2. Why not just put a wire and bolt it like the way you did instead of adding it on the ignition wire?

ANS: It can be used instead of following this kind of modification, what i intend to do was make it clean, and that's how it came out using ground strap, perhaps they'll both the same trick, JUST being clean though.

Read more »

I have been reading all through the net about ground strapping the entire ignition wire in order for the whole system have its own grounding strap instead of relying on the engine chassis ground to i think produce a consistent END part of the ignition to make it more reliable. So why not give a try.

Here what we are going to do is, Adding a direct ground connection on the ignition coil ground down to the cylinder head to where the spark plug is bolted and rely on the engine chassis ground. Materials needed are the following.

Ground strap---this can be found on some computer cables, like the VGA cable, Parallel port cable, etc etc.

We need to remove the other wires inside this ground strap, so that it can be inserted on the ignition wire.

after the removal of all wires being covered with the ground strap, we are ready to insert this strap on the ignition wire.

After minutes of inserting the ground strap must look like this, end to end of the ignition wire must be covered leaving some and twisted at the end for the mounting eyelet to be soldered..The eyelet will be the part to be bolted on the ignition mounting bracket and to anywhere in the cylinder head.

To protect the ground strap from dust, water and any forms of road debris, we need something to hold of also in its place and SHRINK tubing is i think the best for this job. It can be bought at any electronic supply parts nationwide.

This is the final modification of the entire ignition coil, with ignition wire ground strap in place and the eyelet soldered at each end.

Ignition coil bolted to its mounting bracket together with the modded ignition wire ground strap together.

Spark plug cap end with ground connected near the spark plug..

Many people will try to ask,

1.What will be GAINED on doing this kind of MODIFICATION or trick?

ANS: I myself was amazed of doing this kind of mod from a site i recently saw, and logically thinking, why not, thinking outide the box, why the ignition end do not have a proper ground strap and just rely on the engine chassis, and making this mod really make sense that instead of the usual way, why not directly connect such ground as well as ground strapping the entire ignition wire to block any unwanted interference that might affect ignition.

TEST your bike after this mod, if you felt your throttle much crispier than before without this modification, there its a success, for thats why i felt.

2. Why not just put a wire and bolt it like the way you did instead of adding it on the ignition wire?

ANS: It can be used instead of following this kind of modification, what i intend to do was make it clean, and that's how it came out using ground strap, perhaps they'll both the same trick, JUST being clean though.

Testing Motorcycle CDI Ignition Coil

CD ignition coil is a step up transformer that transform the voltage generated by the internal HV converter of a CDI into 20 to 40kv in order to achieve a spark at the tip of the plug. Do not be mistaken, CDI coil differs from TCI coil, and almost all available Ignition coil has only one purpose, To produce an arc to spark plug inside the combustion. Photo shown are some variants of ignition coil used on AC-CDI and DC-CDI. At top is china made ignition coil derived from a certain pioneer brand bike, center coil came from my GY6 scooter, and the bottom taken from my existing suzuki shogun 125cc commuter bike. The article will tell us the basic test of ignition coil, that is, resistance and inductance test. The benefits of knowing their resistance and inductance will tell us if the coil will be providing enough energy for our ignition beyond optimum level.

Primary winding compose of few turns thus resistance reading will show milliohms reading and almost zero when using ordinary DVM, thus inductance may be a better choice for an instrument to test it, while as the secondary compose of a hundred turns, it is capable of resistance test.

here are the variation of reading of those three mentioned CDI coil above

The primary winding of the China made CD coil is about 34 uh, when i tried to take resistance test on this side, i only gain 0.3 ohms

for the GY6 coil, i got 29 uh still with a resistance of 0.3 ohms

and for my OEM ignition coil (suzuki shogun 125cc coil) got a reading of 66 uh but still with a reading of 0.3 ohms.

I did this test to be able to determine how it will affect my ignition before i tried to test it on board my motorcycle with the exception of my OEM. Yes they will all work since they are made for a CD ignition. and this inductance will primarily affect the transfer of energy towards the secondary winding of the coil.

For the secondary winding basic test, i use the resistance check, for my homemade inductance tester can only reach the 1 mh range.

Secondary resistance of the china made was 5.65 kohms

GY6 secondary winding resistance of 3.00 kohms

and OEM stands at 6.57 kohms

Higher resistance reading of the secondary means more number of turns and may transform it to a higher voltage output when the primary is being switched by the ignition controller, but then the primary winding also has an adverse effect on the secondary winding. Only by using HIGH voltage tester, we can assure of the reading, but because ignition coil are HIGHLY shield by epoxy resin, we cannot determine if the theory is in fact true that the more number of turns and higher resistance reading will produce more hotter spark.

Soon i will try to make an IGNITION COIL tester to see how the spark is generated by this three outside the combustion..

but then what we will see outside will differ if its inside due the pressure of the combustion. as of now resistance and inductance test is highly recommended for those who wants to try out different CDI coil available.

I am using by the way the china made coil, rather than my SHOGUN OEM, for a change. :-)

Read more »

Primary winding compose of few turns thus resistance reading will show milliohms reading and almost zero when using ordinary DVM, thus inductance may be a better choice for an instrument to test it, while as the secondary compose of a hundred turns, it is capable of resistance test.

here are the variation of reading of those three mentioned CDI coil above

The primary winding of the China made CD coil is about 34 uh, when i tried to take resistance test on this side, i only gain 0.3 ohms

for the GY6 coil, i got 29 uh still with a resistance of 0.3 ohms

and for my OEM ignition coil (suzuki shogun 125cc coil) got a reading of 66 uh but still with a reading of 0.3 ohms.

I did this test to be able to determine how it will affect my ignition before i tried to test it on board my motorcycle with the exception of my OEM. Yes they will all work since they are made for a CD ignition. and this inductance will primarily affect the transfer of energy towards the secondary winding of the coil.

For the secondary winding basic test, i use the resistance check, for my homemade inductance tester can only reach the 1 mh range.

Secondary resistance of the china made was 5.65 kohms

GY6 secondary winding resistance of 3.00 kohms

and OEM stands at 6.57 kohms

Higher resistance reading of the secondary means more number of turns and may transform it to a higher voltage output when the primary is being switched by the ignition controller, but then the primary winding also has an adverse effect on the secondary winding. Only by using HIGH voltage tester, we can assure of the reading, but because ignition coil are HIGHLY shield by epoxy resin, we cannot determine if the theory is in fact true that the more number of turns and higher resistance reading will produce more hotter spark.

Soon i will try to make an IGNITION COIL tester to see how the spark is generated by this three outside the combustion..

but then what we will see outside will differ if its inside due the pressure of the combustion. as of now resistance and inductance test is highly recommended for those who wants to try out different CDI coil available.

I am using by the way the china made coil, rather than my SHOGUN OEM, for a change. :-)

Shogun Missed Shift

I recently having trouble shifting gears on my suzuki shogun 125cc, Actually, its been 2 years i am encountering missed shifts with my bike, but one day, i got convinced to dismantle my clutch and gear cam on my own when i was running hard on one day at a highway here in my country when my 3rd gear suddenly dropped to second gear on its own making my engine scream hard from my high revving run that day. It is not the first time it happened but too many times so my reaction from there was to pull the clutch lever to make it run free will then dropped my rpm to a maintainable level for my second gear..then shift again. It was scary...

Here is the tearing down of my clutch system and gear shift cam mechanism.

First is to drain the oil before removing the clutch cover..Here we have options. the drain no draining of oil procedure, I chose the drain oil procedure since i'll be changing my oil too. The second system is to lean the bike on its left side so that all the oil be on the magneto side, this to prevent oil from spilling out during clutch cover disassembly, therefore saving your oil for another use.

Second, removing the screws holding the cover to the engine, here i numbered my screws, from 1 to 9..this is my way not to interchanged each one of them..i just dont like having a lose thread somewhere...:-))

Subscribe to:

Posts (Atom)